DIFFERENT TYPES OF CARGO PACKAGING: AN ULTIMATE GUIDE

DIFFERENT TYPES OF CARGO PACKAGING

When shipping goods over long distances by ocean, air, or land, cargo packaging becomes a big challenge for most shippers. It’s often difficult to find the right packaging type that guarantees product safety and security and provides an economical, space-saving solution to stack cargo in a container. Choosing the best cargo packaging type requires much research and experience. Without the assistance of a reputable shipping company, you might end up having your cargo damaged, rotten, or in an unacceptable condition. If you’re looking to ship your freight, read on to learn more about different types of cargo packaging,

Why is freight packaging important?

To ensure the safe and secure transportation of goods on the road, freight packaging is essential. It acts as a protective shield against transportation challenges such as different terrains, sudden stops, and rough weather conditions, safeguarding the cargo.

Packaging is a lot more than just enclosing goods. The road can be unpredictable, with poorly paved surfaces and unexpected stops or collisions. However, well-designed packaging can protect against physical damage during transportation, absorbing impact and preserving the integrity of the goods.

Various goods are vulnerable to contamination during transport, particularly electronics and perishable items. However, with suitable packaging, these goods can be protected from exposure to harmful dust and moisture. Adequate packaging ensures that goods arrive at their destination unscathed by creating a barrier.

Choosing the right material for freight packaging

Each material has its unique properties and handling conditions during shipping. Choosing suitable materials will minimize the risk of damage. It also ensures your goods arrive at their destination in optimal condition.

Factors to Consider When Choosing Packaging Material

Durability: Ensure the material can withstand the physical stresses of transportation. Materials like corrugated cardboard, wood, and metal are often used for their strength and durability.

Weight: The weight of the packaging material can affect shipping costs. Lighter materials such as cardboard or plastic can reduce overall shipping expenses, but it’s essential to balance weight with protection.

Fragility of the Goods: Delicate items require cushioning materials such as foam, bubble wrap, or specialized packaging that can absorb shocks and vibrations during transit.

Cardboard/Fiberboard

Cardboard boxes are a type of cargo packaging that is made from fiberboard. Fiberboard is a type of paper that is made from wood fibers. Cardboard boxes are usually made from two types of fiberboard, brown paperboard, and white paperboard. Brown paperboard is made from recycled paper .

There are three different types of cardboard packaging:

Corrugated Carton: It is well-liked for its affordability, recyclability, strength, and lightness. Corrugated boxes are frequently used in the food sector as well as to package clothing, books, plastic, and other non-breakable commodities because of their high quality and safety.

Double-Walled Corrugated Carton: It is frequently employed in crating. When moving furniture or other large goods, protect them by wrapping them in quality Styrofoam and bubble wrap, packing them tightly to prevent movement, palletizing them, and using strapping to hold them in place.

Double Carton: This type of packing is more frequently used for fragile objects that need particular handlings, such as glass, porcelain, and smaller items. Each of these products needs to be manually wrapped in industrial bubble wrap. These things are then put into an inner shipment box, which goes into an actual shipping box at least 2 to 3 inches deep.

Wooden Cases

Wooden cases are one of the most popular types of cargo packaging due to their durability and versatility. They are typically made from high-quality wood, such as oak or mahogany, and can be either solid or plywood. Wooden cases can be used to transport a variety of items, including heavy machinery, electronics, and even art.

Wooden cases offer several advantages over other types of cargo packaging. They are very strong and can protect your items from damage during transport. They are also relatively lightweight, which makes them easy to move around. Additionally, wooden cases can be stacked on top of each other, which is helpful if you need to transport a large number of items.

Disadvantages of wooden cases include the fact that they can be expensive and they are not always easy to find. Additionally, if you are transporting fragile items, you must pack them carefully to avoid damage.

Wooden Crates

Wooden crates are a type of cargo packaging typically used for shipping heavy or oversized cargo. They are made of wood, often plywood or lumber, and are held together with nails, screws, or bolts. Wooden crates can be customized to fit the dimensions of the shipped item and are often used for products such as machinery, appliances, or furniture. Wooden crates offer protection from impact and vibration during shipping and can be stacked on top of each other.

They are appropriate for wooden packing that is incorporated into the skeleton. An open box may be employed when the contents are sufficiently elastic, only to need little packaging to aid in handling and stacking. They are occasionally used as an exterior package when consolidating cartons or enhancing their protection. Giant machines are frequently transported in the wooden skeleton box.

Palletizing Cargo

Palletizing is a type of cargo packaging in which goods are placed on a pallet and secured for transport. Palletizing cargo has many benefits, including improved safety, efficiency, and security. When done correctly, palletizing can help prevent damage to goods during transportation and make it easier to load and unload cargo. Additionally, palletizing can help optimize space in a shipping container or trailer, allowing more goods to be transported at once. Many goods or commodities can be palletized for a reasonable price to make handling, storing, and protecting them easier. Palletizing or unitizing can significantly lower the cost of packing.

There are six common pallets that fit the different intermodal containers now utilized in global trade. These six common pallets have the following standard sizes (in inches):

1016 x 1219 mm (40″ x 48″) North America

1000 x 1200 mm Europe, Asia

1165 x 1165 mm Australia

1067 x 1067 mm (42″ x 42″) Worldwide

1100 x 1100 mm (43″ x 43″) Asia

800 x 1200 mm Europe

Our Logistics Services From China

Streamline your logistics process, ensure secure and timely delivery of your products, and experience peace of mind with our top-tier China freight forwarding services. Choose Linkway Freight for excellence and nationwide coverage.

Door to Door

We take care of everything! Packing from the departure, freight, customs clearance and transport to the final delivery. Opt for the convenience!

Amazon Shipping

Utilize our Standard Freight service to ensure the safe and compliant delivery of your products to Amazon FBA warehouses.

Warehouse

You need a temporary storage service or a warehousing service under a free trade zone. Contact for further information about price & conditions.

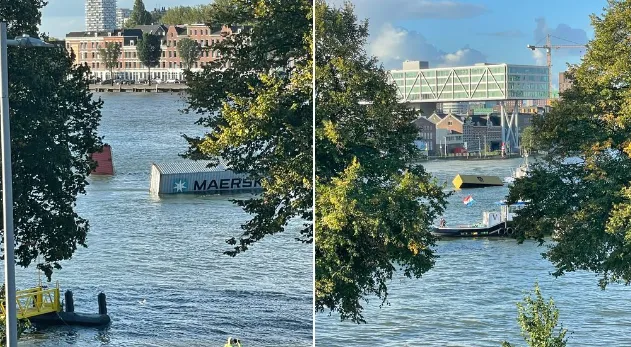

CARGO SHIP ROUTES

Learn more about our key freight shipping trade lanes

Sea and air freight services from: